GROUP COMPANIES

We offer comprehensive proposals for complete coating systems including paint, equipment, robotics, coating apparatus, and environmental measures.

We provide support by making use of our coating technological expertise from hardware to software and materials.

We solve coating and engineering problems from the perspective of an expert.

News Release

2020.12.18

From the approximately 220 foreigners living in Wujin District, Changzhou City, President Takahashi was selected on behalf of the company for contributing to the development of Wujin District economically and socially in 2020.

The title of "Honorary Citizen representatives of Changzhou City" was awarded by Changzhou City Deputy Mayor and Wujin District Commission Secretary Lee Lin.

※Nine awards in 2020 (including four Japanese)

>>The Government of Wujin, Changzhou

>>Wujin Radio and Terevision Station

2020.03.20

In fiscal 2019, the Changzhou Municipal Government commended educational institutions, companies, and individuals who contributed to the field of science education, and received the Innovative Company Award.

* Of the approximately 40 companies that received the corporate award, we are the only foreign-affiliated company.

>>Chinese Academy of Science

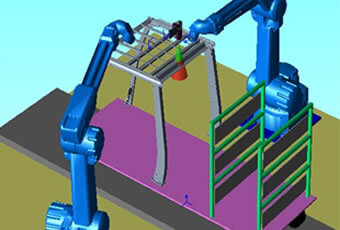

Case study ①

- 【Client】

- Industrial vehicle manufacturer

- 【Description】

- Coating robotics system

This involved the adoption of robotics to carry out the spray coating process that is typically done manually by workers. In conjunction with automation, a two-liquid mixing device was also adopted.

Full automation was realized by equipping existing lines with an automatic workpiece identification system and coating robots.

Tech support for all work was handled by our technical staff.

Preliminary examination by MOTOSIM

Robot simulation

Coating robot: EXP 2750

Work conveyance: power & free conveyor

Paint supply device: two-liquid mixing system

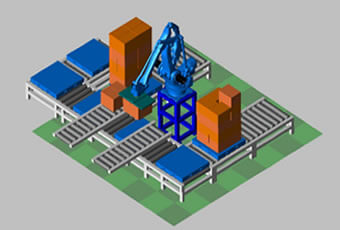

Case study ②

- 【Client】

- Manufacturer of children's household goods

- 【Description】

- Handling robotic system

Our palletizing system for palletizing software MOTOPAL specification was adopted, and was rationalized by making robot teaching and operation even easier.

In addition to designing and manufacturing packing and palletizing lines, we performed teaching for all products.

Preliminary examination by MOTOSIM

Robot simulation

Palletizing robot: MPL 160

Product feeder: accumulation conveyer

Hand: mechanical type → vacuum type, significant improvement in maintainability

24 hr continuous production

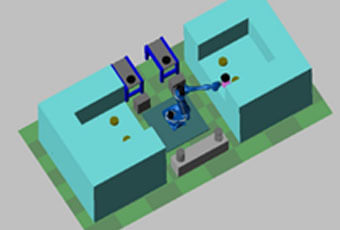

Case study ③

- 【Client】

- Precision reducer manufacturer

- 【Description】

- Handling robot system (1st period: 4 systems, 2nd period: 2 systems, with plans for more than 20 systems in the future)

Loader for NC processing machine combining high-mix compatibility with double hand and automatic reversal work

Unloader unmanned operation was realized. The automatic operation of four processing machines was achieved with a single robot.

Our company has dealt with all workpiece teaching from design and production.

Preliminary examination by MOTOSIM

Robot simulation

General purpose robot: MH-180

Applicable processing machines: vertical type CNC lathes

Handling robot: MH-50II

Applicable processing machines: CNC lathes, vertical CNC lathes

Case study ④

- 【Client】

- Clients in various industries

- 【Description】

- Processing system for various VOCs (environmental measures)

Concentration + catalytic combustion method (installed 2018)

Exhaust wind capacity: approx. 60,000m3/h

*Catalytic combustion involves a combination of electricity and steam (countermeasure against power failure).

Concentration + catalytic combustion method: 3 sets (installed 2018)

Exhaust wind capacity: approx. 60,000m3/h/set

Combustion method: electric

RTO (combustion) method (installed 2018)

Exhaust wind capacity: approx. 50,000m3/h

Combustion method: natural gas

| Company name | Shinanoa Autotech (Changzhou) Co., Ltd. |

|---|---|

| Head Office | 201 R&D HUB 3, Science and Education Town, No.18 Changwu Middle Road, Wujin District, Changzhou Jiangsu Province P.R. 213161 China  |

| Technical Laboratory | Building C West Area 1st floor, No.12 Longhui Road, Wujin High-tech District, Changzhou, Jiangsu

|

| Shanghai Technology Center (Robot Center) | Shanghai Jing'an Jing'ei Road 700, Dainging Center, Plaza D 4 Building, Yaskawa Electric Shanghai Technical Center  |

| Our services | ○ Sales of paint and various production goods ○ Robotic engineering and automated equipment design and construction ○ Environmental and energy-saving equipment design and construction ○ Coating technical instruction, robotic operation and teaching training, maintenance training |

| Capital | ¥30 million |

| Executive officers | CEO Matsudaira Kuniomi President Takahashi Yoshitaka |